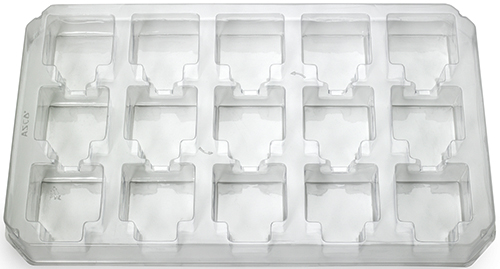

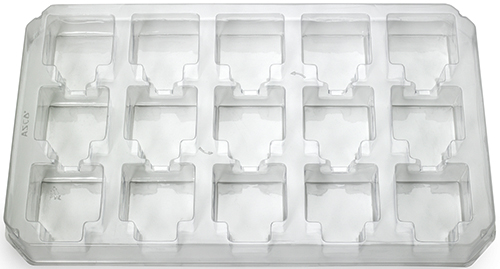

In-process Thermoformed Trays

In-process Trays

Benefits of Thermoformed In-Process Trays

- One of the key benefits is the protection of the sensitive parts when the automated pickers are sorting and packing the partially or fully completed parts that need to go to a different section of the assembly process or be readied for shipment.

- Exact count for automated systems with precise locations is also a crucial benefit.

- These trays function as both in-process as well as shipping trays, depending on the final assembly and your customers packaging requirements.

Any company utilizing the processes or managing the traits in the list below should consider our thermoformed in-process trays.

- Automated process

- Multiple staged assembly process

- Component inspection requirements (even better if there are multiple states of this)

- Sensitive or delicate parts

- Higher dollar values

- Small to medium size and weight

- Utilize racking carts to transport large sets of parts from one area of the plant to another or for storage/staging purposes

Fuel injectors are manufactured utilizing in-process thermoformed trays. In addition, companies that produce electronics utilize thermoformed trays in their manufacturing processes.

|

|

|

| Fuel Injector Tray |

Assembly Component Trays |

If you are thinking about assembly processes, call us for more information. Let us help to get your program running with efficiency.

StockCap is a division of Sinclair & Rush, Inc.