StockCap offers 2-Shot Injection Molding solutions and while all injection molding parts are unique, the benefits of applying 2-shot injection molding makes things even more interesting. Want two colors? Done. Want two materials? Done. And much more can be accomplished by the skill set of our teams to help in producing your most innovative, attractive and multi-purpose parts.

Reasons to Select a 2-shot Injection Molding Solution

What is 2-Shot Injection Molding?

Generally speaking, it is a manufacturing process within a process that delivers unique traits and value to both the manufacturer and the end user. Some of this is the aesthetics of multiple color choices, leading to greater brand awareness. Other characteristics of 2-shot injection molding include functional benefits and often the use of multiple materials are a factor. In the case of this simple screwdriver, the multi-colored appearance can aid branding while the durable and firm material (yellow) provides strength needed in the handle, yet the second material (black) is more soft for easier gripping.

Features of the 2-Shot Process

Several considerations are given when deciding the best manufacturing process for a product. Time to market may critical and equipment capabilities may factor in. Here are some features of the 2-shot injection molding process.

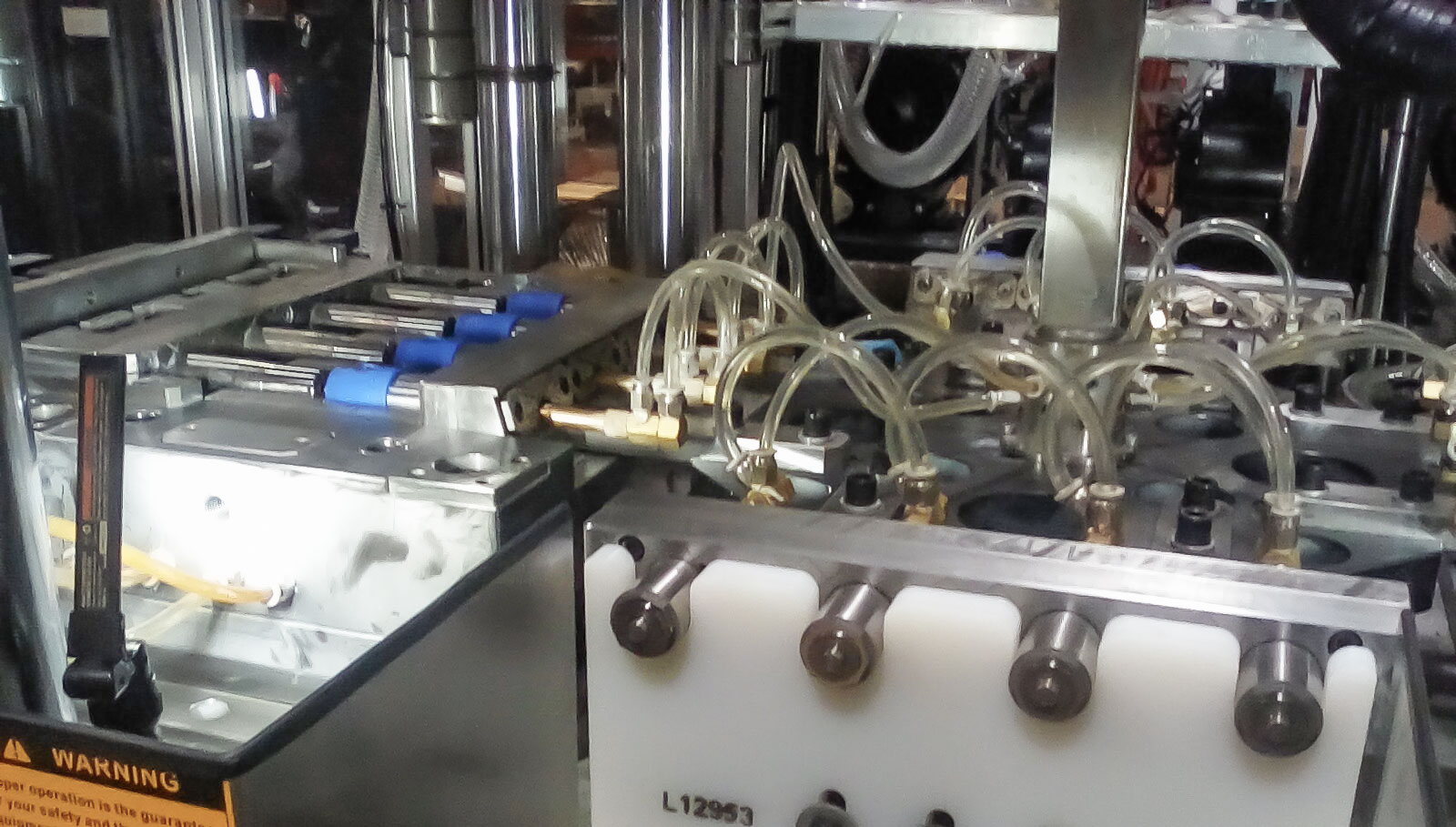

2-Shot Injection Molding Equipment

The two-shot injection molding machines in our USA facility are the latest in state-of-the-art technology and energy efficiency. Current capacity includes production of parts up to 9 inches in length although machines vary.

Achieving multi-featured parts, such as two colors, as one continuous part, produces strength and durability beyond other processes and with efficiencies.

Complex custom designs may effect capacity but our engineering design team analyzes all factors in considering the best solution. StockCap Injection molding specialists will provide guidance to alleviate concerns and direct you to the most effective solution that meet performance, cost, and timing objectives.

Key Industries Applying 2-Shot Injection Molding

Automotive

Consumer Electronics

Medical

For more details about 2-shot injection molding, please follow the link below to a page on our GripWorks site.

Our StockCap Injection molding specialists are waiting to hear from you and learn about your project. Contact us today for more details!