Being the world leader in product protection requires the ability to manufacture products that truly represent the best solution for our clients. To accomplish this, we have invested heavily over the decades to acquire the wide variety of capabilities needed to succeed.

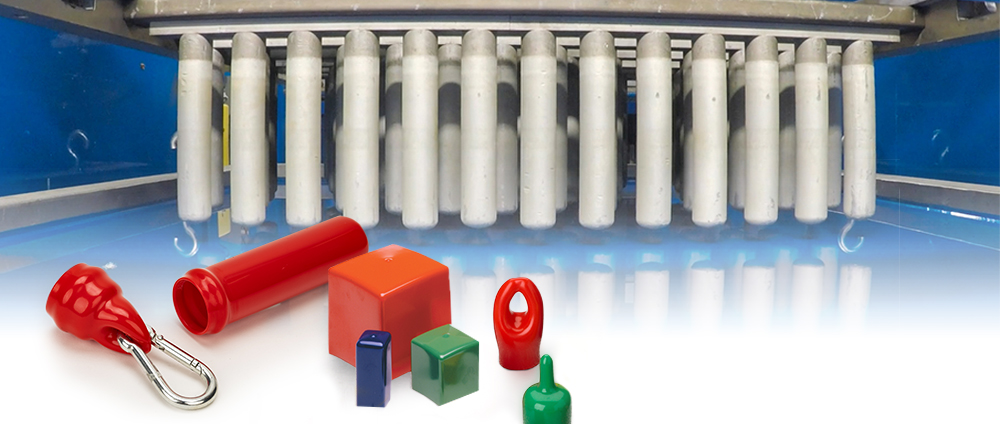

Dip Molding

With dip molding operations on four continents and a history that dates back to 1950, StockCap is arguably the largest and most experienced dip molding company in the world. Over the years, StockCap has established itself as an industry leader by championing innovations in new materials, manufacturing methods and product designs.

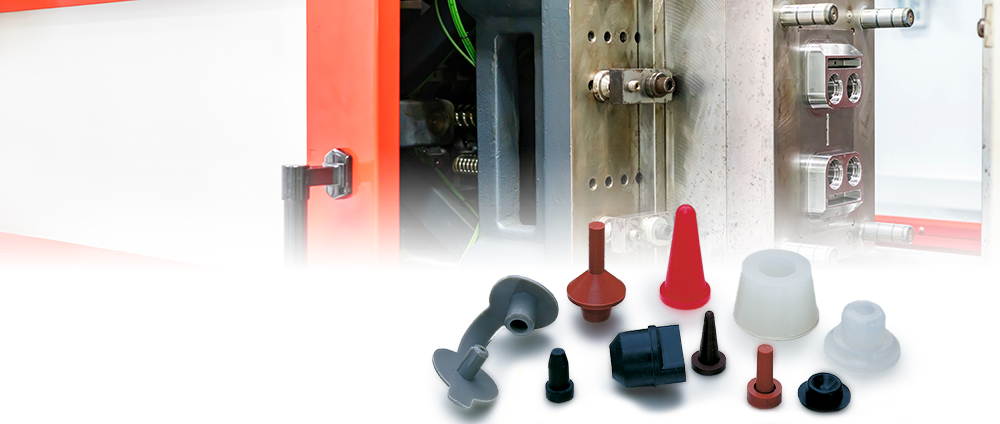

Injection Molding

With over 50 years of design experience and extensive expertise with Creo and NX design and manufacturing software, our engineers have designed parts ranging from caps and plugs to complex industrial closures and components. Our team can assist in all aspects of the process, from concept and prototyping to production and quality assurance.

Rubber Molding

In an effort to expand beyond plastics molding, StockCap invested in compression molding operations and built a supply network to ensure that it could service all of its clients needs for rubber caps, plugs, stoppers and custom covers.

Thermoforming

StockCap’s thermoforming operations are supported worldwide by our experienced design and engineering teams. These specialists aid customers with sizing, design and material specifying to find the best solutions for their specific application.

Our team is armed with the latest CAD and 3D printing technology so it can move from concept and design to prototyping and production in the most efficient and cost-effective manner.

Extrusion

While our extrusion operations primarily support our sister companies, VisiPak and GripWorks, we do have the ability to extrude all types of product protection solutions including plastic packaging tubes with caps and vinyl grips, tubes and sleeves.

Finishing

At StockCap, our service extends beyond molding protective caps, plugs and covers to include a variety of finishing and packaging options. We have an entire facility set up to print, punch, package and more so that your team can focus on what you do best.