StockCap offers Insert Molding solutions to drive your innovation. Insert Molding can streamline your manufacturing process, improve part performance, cut costs – all with a single, integrated molding solution.

Why Choose Insert Molding?

What is Insert Molding?

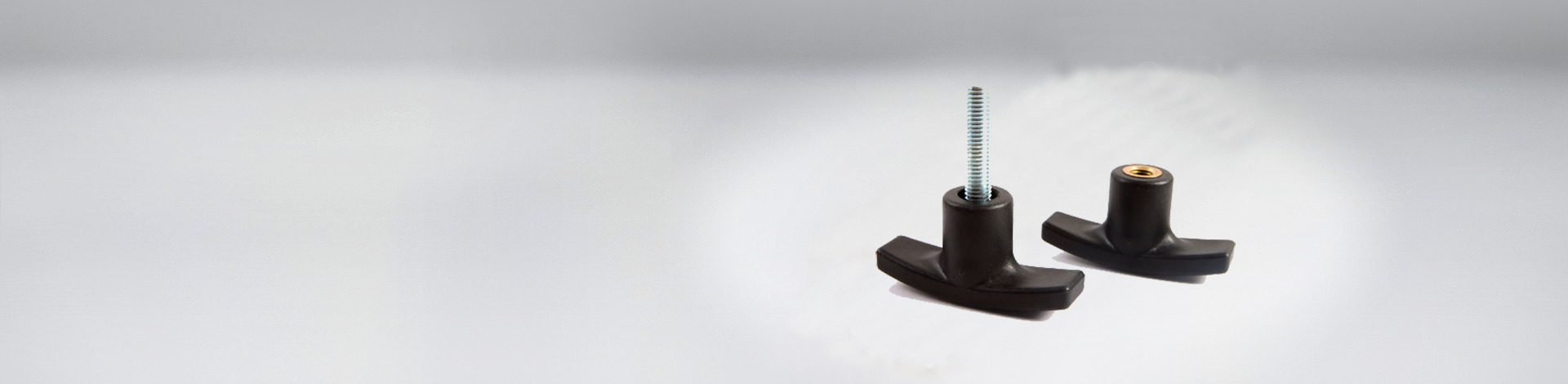

Within an existing injection molding process, insert molding allows for a component to be placed in a mold prior to the resin entering the cavity. As the material is injected it surrounds the component and melds with the material to form a single part. The insert is embedded with the surrounding material to become one unit.

Insert injection molding is best automated with robotics, however, if the volume is small, it is possible to manually insert a component in the mold. Consideration is given to the importance of the integrity of the final part where in some cases this may supersede the volume requirement.

StockCap Insert molding specialists will provide guidance to alleviate concerns and direct you to the most effective solution that meet performance, cost, and timing objectives.