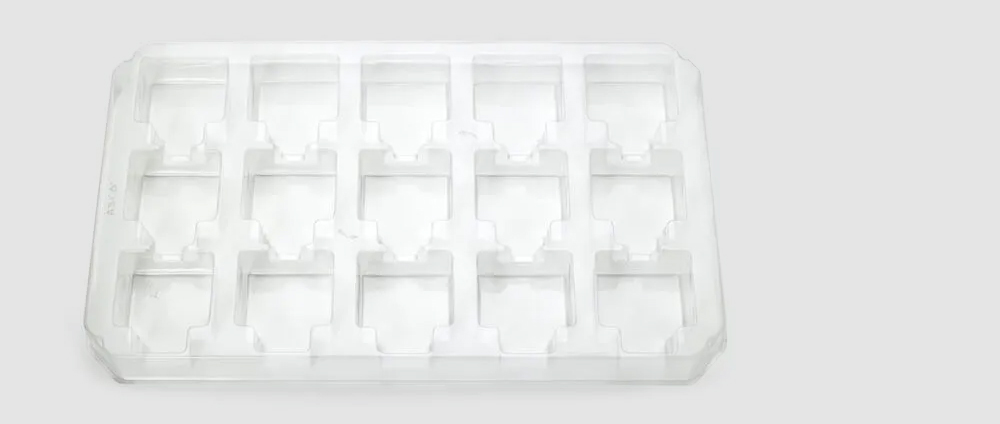

Shipping Trays, Packaging Trays, Dunnage Trays

As companies look to reduce labor in every possible way, StockCap’s Product Protection Specialists have shifted many customers from plastic caps and plugs to custom-designed shipping trays due to these major benefits:

- Superior Product Protection

- Work Well with Robotic Picking Systems

- Light Weight

- Ability to Provide Exact Counts of Parts per Pack

- Ability to Re-use (especially between facilities)

- Empty Trays Can Nest During Shipment

Shipping Trays are Ideal for Use in Protecting and Packaging…

- Sensitive or delicate parts

- Higher dollar value items

- Parts that are small to medium in size and weight

- Parts with strict assembly conditions

- Items that require precise counts of parts per package

- Parts requiring higher levels of cleanliness

Shipping Trays / Dunnage Trays are Ideal for Use in Protecting and Packaging…

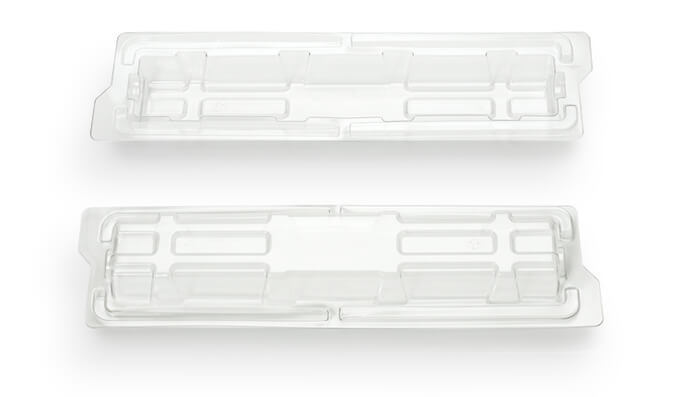

In a world where most of us want to minimize our environmental footprint and employ the concepts of reduce, reuse and recycle, thermoformed shipping trays can help.

- Shipping trays also allow for a greater packing density which reduces in the number of cases being shipped.

- Shipping trays reduce or eliminate the need for loose fill packing materials

- Shipping trays can be reused especially when transported between facilities that are relatively close in geography.

- Plastic shipping trays are generally very easy to recycle

Custom Design

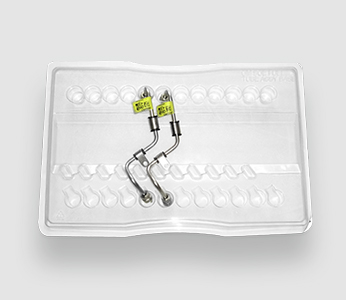

Most shipping trays are custom designed and manufactured to your exact specifications with the most commonly used materials being PVC, PETG and PET. Shown here is a custom tray used to package PVA brushes for the microelectronics industry. Notice the reciprocal snap-perimeter design allowing the plastic tray to snap to itself when placed in an opposing position forming an excellent seal.

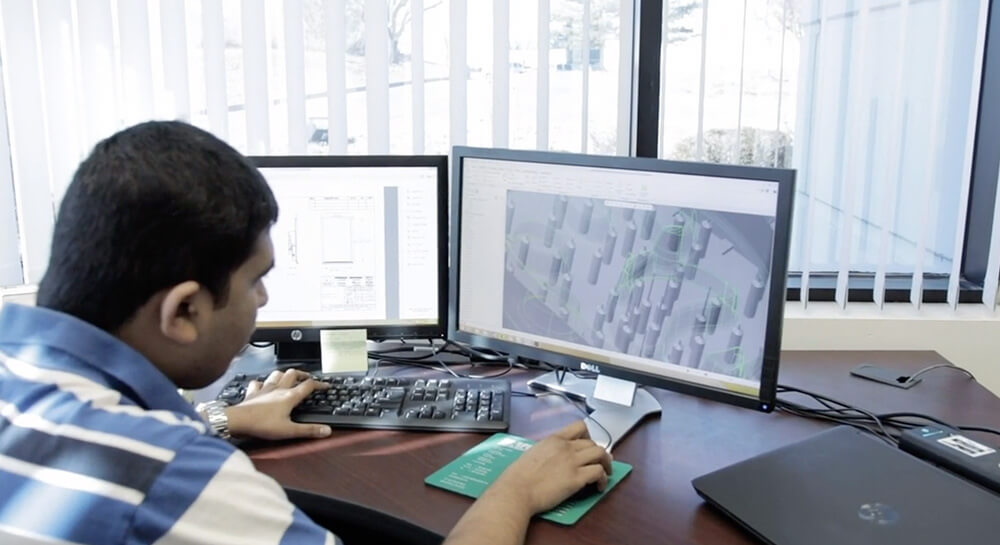

Rapid Prototyping

With extensive experience designing material handling trays and comprehensive prototyping capabilities, our design team can quickly turn your conceptual designs into tangible prototypes, so you can get your product to market faster and more cost-effectively.

- 3D and 2D Computer Aided Design Software

- Start of the Art 3D Laser Scanners

- 3D MicroScribe Digitizing Equipment

- CNC Mold Milling Machine

- 3D Printers for Precise Model & Sample Generation

Manufacturing

Once your parts tray is designed, you can rest assured that it will be manufactured with quality and efficiency in one of our ISO 9001:2015 Certified facilities featuring high-speed inline thermoformers.

- ISO 9001:2015 Certified Facilities

- Cleanroom Manufacturing Options

- Extensive Production Capacity

- Consistent Quality

- U.S. Based Production

Applications

The shipping of hi-speed fuel rails and fuel tube assemblies are examples of products successfully using our thermoformed shipping trays. Additionally, markets that would benefit from our shipping trays include electronics, bearings, high-end filtration products and spark plugs, to name a few.

If you are not using a thermoformed shipping tray and struggle with any of the above topics, please contact us for free consultation. Our years of experience, along with our team of engineering experts, will set you on the right course.