As part of our mission to be the World Leader in Product Protection, StockCap has invested heavily in the thermoforming process. This process not only allows us to manufacture clear plastic caps and covers, but it expands our ability to create custom, “product protection” solutions like shipping trays and thermoformed inserts.

What is Thermoforming?

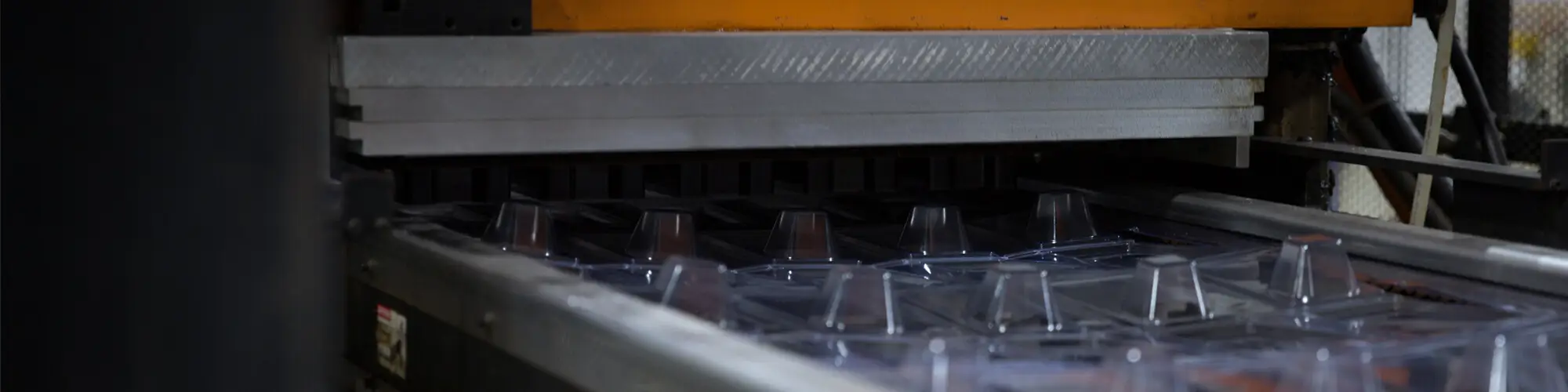

Thermoforming is a process of heating thermoplastic sheet and placing it over a mold until cooled. The thickness of the material determines whether the manufacturing process uses rolled sheets (thin gauge) or pre-cut stacked sheets (thick or heavy gauge). Thin gauge material is dominant in the disposable packaging sector, especially in the retail markets. Heavy or thick gauge material is commonly used as permanent components in such things as refrigerators, automobiles and spas to name a few. PVC is the most commonly used material in any thermoforming production.

All StockCap thermoforming products are manufactured in the USA.

Thin Gauge Thermoforming

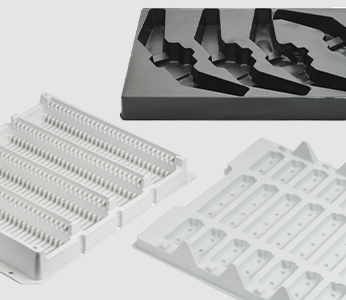

StockCap manufactures a wide variety of thermoformed solutions that are ideal for nearly any product line. Aside the popular clear plastic clamshells and blister packaging, thermoformed trays and inserts for industrial uses is our niche. These are typically high volume, custom designed trays, often reusable.

Heavy Gauge Thermoforming

Heavy gauge thermoformed products need to be sturdy and are typically larger parts. Volume requirements are frequently much smaller than a thin gauge part. Heavy gauge parts are designed to exist for very long periods of time. StockCap produces strong durable parts with excellent strength to weight ratio.

Design Experience

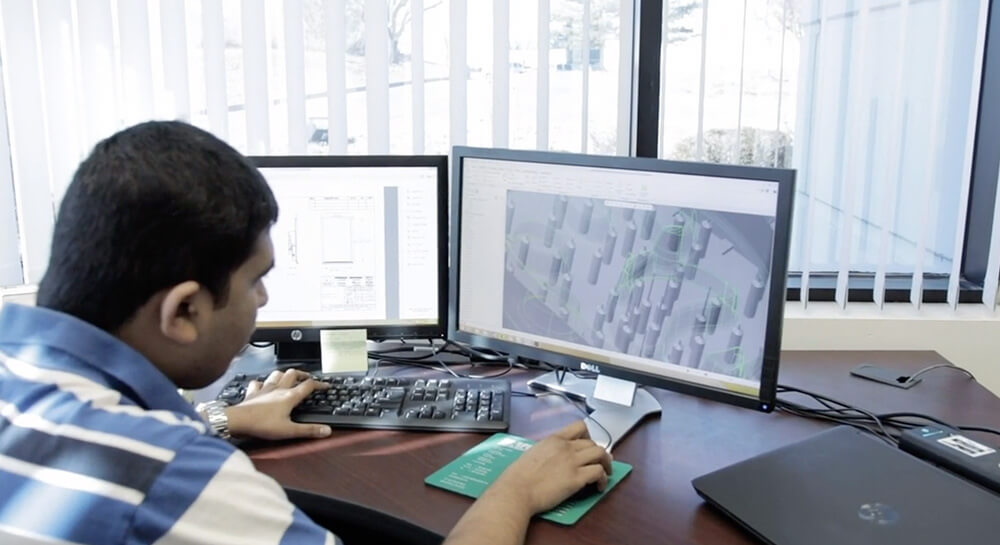

With over 70+ years of design experience, our team can advise clients on the best design and material options for their specific application. We use PTC Creo and Siemens NX programs to seamlessly integrate the design and tooling fabrication processes.

Rapid Prototyping

With extensive experience designing material handling trays and comprehensive prototyping capabilities, our design team can quickly turn your conceptual designs into tangible prototypes, so you can get your product to market faster and more cost-effectively.

- 3D and 2D Computer Aided Design Software

- Start of the Art 3D Laser Scanners

- 3D MicroScribe Digitizing Equipment

- CNC Mold Milling Machine

- 3D Printers for Precise Model & Sample Generation

Experienced in Processing Multiple Materials

Our many years of experience combined with the variety of equipment capabilities allows us to process many types of materials, including HIPS, PET, PETG, ABS, PVC, OPS, HDPE, and PP as well as…

Our Capabilities

As a custom thermoformer, we have an extensive amount of thermoforming equipment that allows us to manufacture parts in the most cost-effective manner. Our primary expertise lies in producing high volume parts – both high-precision and industry standard.

- Rigid materials from .008” – .080” in thickness

- Part sizes from less than 1” and up to 36”

Our equipment goes beyond that of a typical thermoforming company. We have engineered unique machinery for specialized applications.

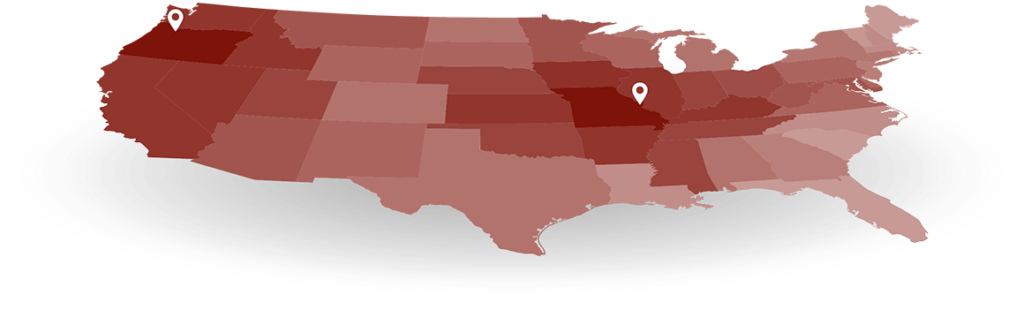

National Manufacturing Locations

As part of the Sinclair & Rush family of companies, we have thermoforming operations centrally located in St. Louis, Missouri and on the west coast in Portland, Oregon.